500c High Resolution Shear Profile Measurements In Entangled Polymers

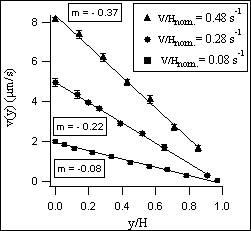

We use confocal microscopy and particle image velocimetry to directly visualize polymer flow in a custom-built, planar-Couette rheometer. Polybutadiene (melt Mw = 200K, 788K) solutions spanning a range of entanglement densities (8 ≤ N/Ne ≤ 56) are seeded with 250-300 nm particle tracers and sheared in narrow gaps ~ 35 μm. Compared to Couette and cone & plate geometries, our small aspect ratio (as < 1/143) parallel plate shear cell is a more rigorous setting in which to explore banding in entangled polymer flows. As the imposed shear rate increases, we find that not only does the velocity at the boundaries violate the no-slip condition, but that there are increasingly large differences between the imposed and measured rates. Despite these observations, importantly, the measured velocity profiles are generally linear (see Figure), even for shear rates well within the non-Newtonian shear regime. This finding disagrees with recent reports that shear banding is a characteristic flow response of entangled polymers, and instead points to interfacial slip as an important source of strain loss. The measured shear rates and shear stresses are used to characterize slip. We find two slip regimes; the transition to the highly non-linear second regime occurs at shear stresses comparable to the elastic modulus of the entangled polymer network. Our results are consistent both with theories for polymer slip and with published data obtained via other techniques. However, we also find that at very high dimensionless shear rates, a non-linearity in the velocity profile emerges near the moving plate. Motivated in part by this last result, we complement the confocal rheology with large-gap velocimetry using micron-sized tracers to investigate the limits and/ or range of applicability of the banding and interfacial slip phenomena. FIGURE: Velocity profiles for PBD200K, φ=0.4 solution; y/H=0 and y/H=1 are the top & bottom plates respectively