399c Design, Development and Operation of a Novel Recirculating Liquid/solids Reactor Based on a Type 2 Draft Tube Spout Fluid Bed

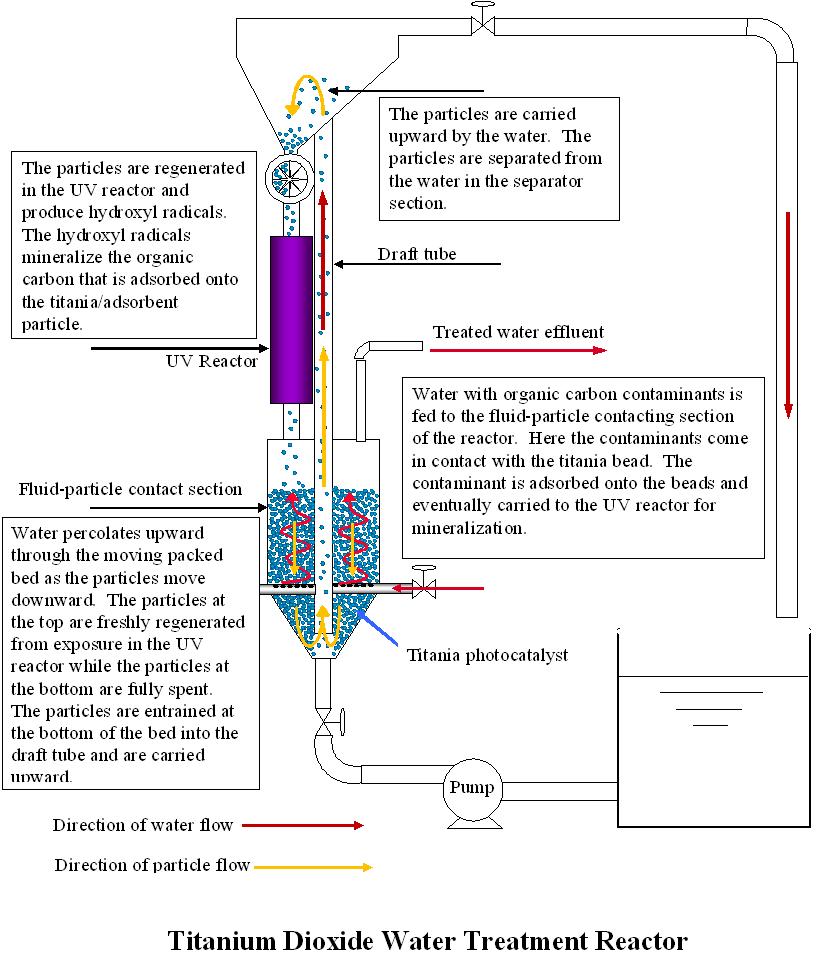

There is a wide variety of multiphase reactions that require the solid phase to be regenerated. Very often the primary and regeneration reactions must be run under different operating conditions. A novel, next-generation draft tube spout fluid bed has been developed to provide a flexible and quantifiable system to optimize the operating conditions of a given fluid/solids regeneration reaction. Separating the locations of the annulus and draft tube effluent converts a standard DTSFB into a second generation (type 2) DTSFB. By separating the effluents of the annulus and the draft tube, the pressure drops across these two regions and the fluid flows through them can be independently varied. This allows the particle velocity and the solids concentration in the draft tube to be determined independently. Therefore, for a given solids circulation rate, both the solids concentration and particle velocity can be determined to accommodate the conditions at which the regeneration may take place. A type 2 DTSFB has been designed and constructed to run advanced oxidation reactions that use titanium dioxide to generate hydroxyl radicals to destroy organics in water. The reactor has been used to collect hydraulic data that were compared to existing fluid/solid transport correlations. The inlet section to the draft tube was also examined to determine the maximum and minimum operating limits of the inlet length. The maximum limit for solids concentration in the draft tube was also examined and compared to literature data. The type 2 DTSFB has been shown to be an efficient recycle reactor that can be used to run reactions that require the solids to be regenerated. Because the annulus need not be fluidized, the particles that approach the inlet to the draft tube have the longest residence time and are not randomly mixed with those that have been freshly regenerated. Other novel applications and configurations of the type 2 DTSFB are also discussed. The flexibility of the type 2 DTSFB allows them to be cascaded into a series that allows two or more reactions that have differing rates to be run continuously.